BIOGAS Energy

The byproduct of anaerobic digestion of organic materials are commonly referred biogas Biogas biogas certain controlled conditions. Biogas

Methane forms Microbes or Methanogenesis:-

Acetate, carbon dioxide and molecular hydrogen can be directly utilized as a substrate by the group of anaerobic micro-organisms called methane genesis or methane forming bacteria. Methane can be synthesized via two different pathways, of which one involves acetate and the other molecular hydrogen. The estimations indicated that about 70% of the methane is produced from acetate and 30% comes from hydrogen. The Volatile Fatty Acids (VFA) accumulation is to be avoided in thedigester

Stoichiometric

The bio - methanation process is carried out by the symbiotic action of methane and acid producing bacteria. The interrelated behaviors of all classes of bacteria create the environment for each other to survive and growsimultaneously , The estimation of biogas Stoichiometric equation

The simple equation is considered byGhaly biogas

CnHaOb + (4n-a-2b) H 2 O → (4n + a-2b) / 8 CH 4+ (4n-a + 2b)

Veziroglu biogas

(CaHbOcNd + (4a-b-2c + 3d) / 4H2O → (4a + b-2c-3d) / 8CH4 + (4a-b + 2c + 3d) / 8CO2 + dNH3

The formula for the conversion of organic substance in an aqueous environment into CH4 & CO2 and into ammonia and hydrogensulphide

CnHaObNcSd + (4n-a + 2b + 3c + 2d) / 8H2O → (4n-a + 2b + 3c + 2d / 8CO2 + (4n + a-2b-3c-2d) / 8 CH4 + cNH3 + d H2S

It is interesting to note that any organic matter will generatebiogas

Process Parameters Affecting The Biogas Production:-

All kinds of organic waste such as kitchen waste and garden waste, cattle dung and sewage etc.can biogas

1). Amount of organic material

2). Digestibility of the material

3). A combination of microbial and engineering factors such as

a). Organic Loading rates: biogas biogas reactor

According, the loading rate should be in the range of 1-1.5 Kg volatile solids/m³digester biogas digesters

b).pH : biogas rate which for

The control of decrease in pH of an anaerobic reactor may be done by stopping the feeding and increase the buffering capacityeg through

c). Alkalinity:

d). Temperature: biogas anaerobic digester

Temperature Range Retention Time

Methanogenesis psycrophillic biogas

e). Carbon to Nitrogen Ratio:-

Microorganisms an biogas

f). Nutrients and Trace Elements:-

Microorganisms require the macro and micro nutrients as trace elements such as phosphorous, nitrogen, sulfur, calcium, potassium, iron, nickel, cobalt, zinc and copper. These areessential

g). Hydraulic Retention Time (HRT)

I with operating temperature of the anaerobic digester. It may be defined as the average time a volume element of the liquid medium resides inside the reactor. A better production ofbiogas

Anaerobic digestion can be performed with a relatively short HRT i.e. "High rate"

systems ow rate" systems are normally used to digest slurries and solid wastes while high rate systems are usually used for treatment of waste water.

h). Toxicity:-

Methanogens

Nickel Sulphur

i

PROCESS:-

The different pathways of the bio-methanation process are suggested by several investigators. Macro level energy conversion of organic waste into bio-menthanation formation of methane and carbon dioxide besides some part of it remains in the effluent.

A simple flow chart may describe the three step process of bio-methanation.

Hydrolysis:

Acid Formation:

Methane Formation:

Cell

↑ →→→→ Synthesis

↑

↑

Energy in ↑ →→→→ Effluent

Organic ↓ Substrate

Matter ↓

↓

↓ →→→→ Methane and

Carbon Dioxide

Production

Energy Conversion in Process

Each stage is being carried out by different types of bacteria with different environmental requirements.

Hydrolysis:-

It is the first step in anaerobic degradation and also the rate limiting step. The hydrolysis of organic polymers such as polysaccharides, fats and proteins convert these polymers into smaller units such as sugars, long chain fatty acids and amino acids. This group of bacteria called as facultative anaerobes/microbes.

Acid forming Microbes or Acitogenesis:-

The sugars, long chain fatty acids and amino acids resulting from hydrolysis are used as substrates by a wide variety of bacterial generation of different fermentative

|

| Three Stage Process of Bio- |

Acetate, carbon dioxide and molecular hydrogen can be directly utilized as a substrate by the group of anaerobic micro-organisms called methane genesis or methane forming bacteria. Methane can be synthesized via two different pathways, of which one involves acetate and the other molecular hydrogen. The estimations indicated that about 70% of the methane is produced from acetate and 30% comes from hydrogen. The Volatile Fatty Acids (VFA) accumulation is to be avoided in the

The bio - methanation process is carried out by the symbiotic action of methane and acid producing bacteria. The interrelated behaviors of all classes of bacteria create the environment for each other to survive and grow

The simple equation is considered by

CnHaOb + (4n-a-2b) H 2 O → (4n + a-2b) / 8 CH 4+ (4n-a + 2b)

(CaHbOcNd + (4a-b-2c + 3d) / 4H2O → (4a + b-2c-3d) / 8CH4 + (4a-b + 2c + 3d) / 8CO2 + dNH3

The formula for the conversion of organic substance in an aqueous environment into CH4 & CO2 and into ammonia and hydrogen

CnHaObNcSd + (4n-a + 2b + 3c + 2d) / 8H2O → (4n-a + 2b + 3c + 2d / 8CO2 + (4n + a-2b-3c-2d) / 8 CH4 + cNH3 + d H2S

It is interesting to note that any organic matter will generate

Process Parameters Affecting The Biogas Production

All kinds of organic waste such as kitchen waste and garden waste, cattle dung and sewage etc.

1). Amount of organic material

2). Digestibility of the material

3). A combination of microbial and engineering factors such as

a). Organic Loading rates

According, the loading rate should be in the range of 1-1.5 Kg volatile solids/m³

b).

The control of decrease in pH of an anaerobic reactor may be done by stopping the feeding and increase the buffering capacity

c). Alkalinity

d). Temperature

Temperature Range Retention Time

-

Psychrophillic -

Mesophillic -

Thermophillic

|

| Temperature Effect on Gas Production |

f). Nutrients and Trace Elements:-

Microorganisms require the macro and micro nutrients as trace elements such as phosphorous, nitrogen, sulfur, calcium, potassium, iron, nickel, cobalt, zinc and copper. These are

g). Hydraulic Retention Time (HRT)

I with operating temperature of the anaerobic digester. It may be defined as the average time a volume element of the liquid medium resides inside the reactor. A better production of

Anaerobic digestion can be performed with a relatively short HRT i.e. "H

|

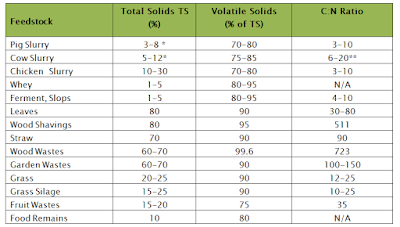

| Feedstock Characteristic |

Substance mg / l

Copper → 10-250

Calcium → 8000

Sodium → 8000

Magnesium → 3000

Zinc → 350-1000

Mixing is a control process to keep uniform the pH and other environmental conditions of slurry in the digester methanogenic

BENEFITS:-

The cooking in rural area is still largely depends on the use of traditional cook stoves (Chulla's). They are burning dung cake, fire-wood and agricultural waste in addition to keroseneupto

The cooking in rural area is still largely depends on the use of traditional cook stoves (Chulla's). They are burning dung cake, fire-wood and agricultural waste in addition to kerosene

- Reduction in pollution due to burning of dung and other other biomass materials.

- The rural people would not be dependent on wood is used for cooking. The deforestation and ecological imbalances can be reduced.

- In rural areas instead of kerosene the

biogas - The most important benefit would be in keeping the clean inhabitation and

environment form - The combustion of

biogas biogas comes from plant matter that fixed this carbon from atmospheric. Thus, Biogas production is carbon neutral and does not add to greenhouse gas emissions.

Video Regarding:

Comments