Very Early Smoke Detection Apparatus:-

VESDA ® (an abbreviation of Very Early Smoke Detection Apparatus) is a laser-based smoke detection system. The name VESDA ® has become a generic name for most air sampling applications. The name VESDA ® is a trademark of Xtralis.

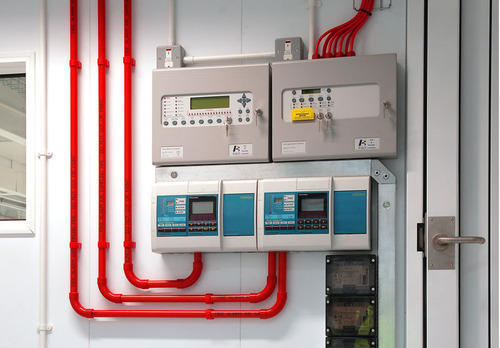

|

| VESDA System |

What is VESDA ®?

VESDA ® is a laser-based smoke detector, which means it is a very good smoke detector. VESDA ® smoke detectors have been operating in specialist fire detection applications for over 20 years. VESDA ® is the most advanced aspirating smoke detection equipment in the fire industry. VESDA ® smoke detectors hold more certifications than any other aspirating smoke detectors in the world.

How does VESDA ® work?

|

| VESDA AIRFLOW |

A VESDA ® detector is much like a vacuum cleaner. VESDA® works by continually drawing air from the protected environment into the pipe network via a high-efficiency aspirator. A sample of this air is then passed through a dual-stage filter. The first stage removes dust and dirt from the air sample before it allows the sample to enter the laser detection chamber for smoke detection. The second (ultra-fine) stage provides an additional clean air supply to keep the detector’s optical surfaces free from contamination, ensuring stable calibration and long detector life.

Why do we use VESDA ®?

The aspirating smoke detection market has changed over recent years. VESDA ® smoke detection was traditionally used for specialist smoke detection environment. VESDA ® smoke detection is now used more extensively in non-specialist fire detection applications and of course the traditional specialist market. VESDA ® detectors are normally used where high smoke sensitivity is required. VESDA ® detection works far more efficiently in an area where there is high airflow, such as computer rooms, Telecoms, etc.

Where do we use VESDA ® smoke detectors?

VESDA ® detection for warehouses

VESDA ® smoke detection is a suitable replacement for conventional smoke detection where accessibility is limited. For example, VESDA ® detection will be better suited to a warehouse with smoke detectors situated at high levels. Conventional smoke detectors can become faulty and access equipment will need to be deployed, this can be extremely disruptive to operation and it is also dangerous. VESDA ® smoke detection eliminates this issue as the aspirating pipework will be located at high levels and the VESDA ® detector will be located at accessible levels. Aspirating pipe will replace the smoke detectors at a high level, with holes in the aspirating pipe replacing the smoke detectors. VESDA ® smoke detectors have 18000 events log memory. Smoke levels can be tracked and identified against time and density. Commissioning VESDA ® should include measure smoke tests. There are different tests for different applications, these are measure with a set amount of smoke and readings from the VESDA ® detectors tell us how the system will perform in a real-life situation.

VESDA ® detection for cold rooms

VESDA ® smoke detection is commonly used where temperatures are not suitable for other types of smoke detection. For example, a cold room operating temperatures ranging from 20 C to -20 C is an ideal environment for VESDA ® smoke detection. Cold temperatures will ice up the optical chambers of conventional smoke detectors rendering the system useless. VESDA ® detectors are located outside the cold environment, with aspirating pipework located within the risk or outside the risk with capillary smoke sampling heads located within the risk! The cold air is then drawn to the VESDA ® smoke detector and is naturally heated before it arrives at the VESDA ® laser chamber. The condensation is collected at a condensate water trap and dry air arrives for sampling by the VESDA ® detector. In extreme cases, air dryers may be needed, but in the most, are not required for the VESDA ® system.

VESDA ® detection for computer rooms

VESDA ® detection is ideal for an area that has high airflow. Conventional smoke detectors struggle to activate with voluminous air passing through their chambers. VESDA ® detectors draw smoke from the aspirating pipe and the holes in the pipe collectively capture the air and draw it back to the VESDA ® detector. Fire Suppression Limited has conducted a test that conclusively proves that VESDA ® smoke detection is far more responsive than conventional smoke detectors. Measured tests again provide reports and samples of how the VESDA ® detectors will operate in a high airflow environment.

VESDA ® detection for Fire Suppression environments

VESDA ® detection with Fire Suppression is a fantastic combination. With ever-increasing environmental responsibilities, it is essential that a fire suppression system should deploy unnecessarily. VESDA ® smoke detection use in conjunction with conventional smoke detection is a perfect match. Preferably VESDA ® detection samples the air across the return plenums of the air conditioning systems which provide primary smoke detection! An alert alarm can be raised and human intervention can prevent the gas from discharging! VESDA ® can also be used as a double knock system, which provides the most suitable fire detection model for any automatic fire suppression system!

VESDA ® smoke detection for Ceiling voids

With the recommendations of the BS5839 that stipulates that any ceiling void over 800mm in depth must be treated as the area below. With today's modern architecture, many ceilings are a solid ceiling with little access. VESDA® smoke detection is ideal for this, as the aspirating pipework will replace the conventional smoke detection, with the VESDA ® smoke detector in an accessible location.

VESDA ® smoke detection in lift shafts

VESDA ® smoke detection for lift shafts enhanced that smoke detection within what is a highly sensitive area. It also makes maintenance safe as the engineer will not need to get into the lift shaft for maintenance purposes.

The VESDA ® detection range

VESDA® detectors range from the VESDA®LaserFocus range, through to the VESDA® LaserCompact, VESDA ® LaserPlus to the VESDA ® LaserScanner.

The VESDA ® LaserFOCUS (VLF)

The VESDA ® Laser FOCUS has been equipped with a clear, intuitive, circular smoke dial display that gives unprecedented event identification, allowing for immediate risk assessment and preventative action. Another example of why VESDA ® fire detection systems are regarded as the best in the world. This VESDA ® smoke detection unit, with its' well-positioned LEDs and related icons, allows for instant identification of smoke growth and alarm conditions, even from a distance.

|

| VESDA Work |

Why do we use VESDA ®?

The aspirating smoke detection market has changed over recent years. VESDA ® smoke detection was traditionally used for specialist smoke detection environment. VESDA ® smoke detection is now used more extensively in non-specialist fire detection applications and of course the traditional specialist market. VESDA ® detectors are normally used where high smoke sensitivity is required. VESDA ® detection works far more efficiently in an area where there is high airflow, such as computer rooms, Telecoms, etc.

Where do we use VESDA ® smoke detectors?

VESDA ® detection for warehouses

VESDA ® smoke detection is a suitable replacement for conventional smoke detection where accessibility is limited. For example, VESDA ® detection will be better suited to a warehouse with smoke detectors situated at high levels. Conventional smoke detectors can become faulty and access equipment will need to be deployed, this can be extremely disruptive to operation and it is also dangerous. VESDA ® smoke detection eliminates this issue as the aspirating pipework will be located at high levels and the VESDA ® detector will be located at accessible levels. Aspirating pipe will replace the smoke detectors at a high level, with holes in the aspirating pipe replacing the smoke detectors. VESDA ® smoke detectors have 18000 events log memory. Smoke levels can be tracked and identified against time and density. Commissioning VESDA ® should include measure smoke tests. There are different tests for different applications, these are measure with a set amount of smoke and readings from the VESDA ® detectors tell us how the system will perform in a real-life situation.

|

| Warehouse |

VESDA ® smoke detection is commonly used where temperatures are not suitable for other types of smoke detection. For example, a cold room operating temperatures ranging from 20 C to -20 C is an ideal environment for VESDA ® smoke detection. Cold temperatures will ice up the optical chambers of conventional smoke detectors rendering the system useless. VESDA ® detectors are located outside the cold environment, with aspirating pipework located within the risk or outside the risk with capillary smoke sampling heads located within the risk! The cold air is then drawn to the VESDA ® smoke detector and is naturally heated before it arrives at the VESDA ® laser chamber. The condensation is collected at a condensate water trap and dry air arrives for sampling by the VESDA ® detector. In extreme cases, air dryers may be needed, but in the most, are not required for the VESDA ® system.

|

| Cold Room |

VESDA ® detection is ideal for an area that has high airflow. Conventional smoke detectors struggle to activate with voluminous air passing through their chambers. VESDA ® detectors draw smoke from the aspirating pipe and the holes in the pipe collectively capture the air and draw it back to the VESDA ® detector. Fire Suppression Limited has conducted a test that conclusively proves that VESDA ® smoke detection is far more responsive than conventional smoke detectors. Measured tests again provide reports and samples of how the VESDA ® detectors will operate in a high airflow environment.

VESDA ® detection for Fire Suppression environments

VESDA ® detection with Fire Suppression is a fantastic combination. With ever-increasing environmental responsibilities, it is essential that a fire suppression system should deploy unnecessarily. VESDA ® smoke detection use in conjunction with conventional smoke detection is a perfect match. Preferably VESDA ® detection samples the air across the return plenums of the air conditioning systems which provide primary smoke detection! An alert alarm can be raised and human intervention can prevent the gas from discharging! VESDA ® can also be used as a double knock system, which provides the most suitable fire detection model for any automatic fire suppression system!

VESDA ® smoke detection for Ceiling voids

With the recommendations of the BS5839 that stipulates that any ceiling void over 800mm in depth must be treated as the area below. With today's modern architecture, many ceilings are a solid ceiling with little access. VESDA® smoke detection is ideal for this, as the aspirating pipework will replace the conventional smoke detection, with the VESDA ® smoke detector in an accessible location.

|

| Ceiling Voids |

VESDA ® smoke detection in lift shafts

VESDA ® smoke detection for lift shafts enhanced that smoke detection within what is a highly sensitive area. It also makes maintenance safe as the engineer will not need to get into the lift shaft for maintenance purposes.

|

| Lift Shaft |

The VESDA ® detection range

VESDA® detectors range from the VESDA®LaserFocus range, through to the VESDA® LaserCompact, VESDA ® LaserPlus to the VESDA ® LaserScanner.

The VESDA ® Laser FOCUS has been equipped with a clear, intuitive, circular smoke dial display that gives unprecedented event identification, allowing for immediate risk assessment and preventative action. Another example of why VESDA ® fire detection systems are regarded as the best in the world. This VESDA ® smoke detection unit, with its' well-positioned LEDs and related icons, allows for instant identification of smoke growth and alarm conditions, even from a distance.

Features

- Out-of-the-Box Installation and Commissioning

- Ultrasonic Air Flow Sensing

- Laser-Based Absolute Smoke Detection

- Pre-engineered pipe network designs

- Programmable Alarm Thresholds

- Dual Stage Air Filtration

- Instant Recognition Display

- Instant Fault Finder

- AutoLearn Smoke

- AutoLearn Flow

- Field Service Access Door

- Multiple Event Logging in separate logs

- Event log up to 18000 events

- Of. in/online con. duration capability

- Up to 250 m2 (2500 sq. ft.) coverage*

The VESDA ® LaserCOMPACT uses the approved core LaserPLUS detection technology that has been proven in a wide range of environments. More than the run of the mill fire alarms, the LaserCOMPACT operates by continually drawing air from a protected environment via a high- efficiency aspirator and sampling pipe network to a central highly sensitive detector. Once the air passes the flow sensor it is passed through a dual-stage filter. The first stage removes dust and dirt from the air before it enters the chamber for smoke detection. The second ultrafine stage provides a clean air supply to form clean air barriers. These clean air barriers protect the optical surfaces from contamination, ensuring the extended lifespan of the detector. Filtration and clean air management are critical in providing high sensitivity detection and eliminating the need for chamber cleaning. This ensures that the internal surfaces of the detector are not exposed to contamination.

The LaserCOMPACT is a highly efficient smoke and fire detector which samples the air passing through the unit with a fine laser beam. The presence of smoke causes light scattering within the chamber that is detected by a very sensitive receiver circuit. The signal is processed and sent to a display that indicates the level of smoke either by a bar graph, alarm threshold indicators and/or graphic display. Specific response procedures can be initiated by the three adjustable alarm thresholds, ensuring a controlled and timely response to interface to fire alarm and building management systems. LaserCOMPACT is available in two versions, one that interfaces via relays only (RO) or across either the relays or VESDA ®net (VN).

Features

- Reduced size compared to LaserPLUS and LaserSCANNER detectors

- Wide sensitivity range

- Each detector can cover an area of up to 800 m2 (8000 sq. ft.)

- Up to three programmable alarm thresholds

- Programmable relays

- AutoLearn feature

- One pipe inlet that can be split into two pipes

- Dual-stage air filter cartridge

- Option for inverted mounting

- High-efficiency aspirator

- Airflow monitoring

- Optional remote display and relay capability

- Active fault monitoring

- Easy cable termination

- Event log to 12000 events

- RO Version: Relay Only version for stand-alone LaserCOMPACT

- VN Version: VESDA ®net (VN) version for networked LaserCOMPACT

- Remote modules available (VN version only) to meet site-specific requirements

- Three programmable general-purpose input functions

- PC capable programming and monitoring

The VESDA ® LaserPLUS (VLP)

The VESDA ® LaserPLUS is an aspirating smoke detection unit providing very early warning of fire conditions by drawing air samples through an air sampling pipe network. The detector chamber can detect the presence of smoke at very low concentrations. The embedded and PC software complementing the LaserPLUS provides a wide range of user-defined parameters and reporting capabilities. This fire detection system easily interfaces with fire warning and fire suppression release systems and can be easily integrated into a building management system.

|

| VESDA LaserPLUS |

Features

- The LaserPLUS features make it a versatile smoke detection product:

- Each detector can cover an area up to 2,000 m2 (20,000 sq. ft.)

- Wide sensitivity range

- Four programmable alarm thresholds

- AutoLearn feature

- Four pipe Inlets

- Individual pipe flow monitoring

- Replaceable air filter cartridge

- Option for inverted mounting

- Recessed mounting option

- Modular to meet site-specific requirements

- Modular Display Module and LCD Programmer

- Seven programmable relays

- High-efficiency aspirator

- Programmable general purpose Input

- PC capable programming and monitoring

- Multilingual displays

- Event log for up to 18,000 events

The VESDA ® LaserSCANNER (VLS)

The VESDA ® LaserSCANNER can monitor and individually report on four sectors in the protected area. The VESDA ® LaserSCANNER is an aspirating smoke detector providing very early warning of fire conditions by drawing air samples through an air sampling pipe network. The detector chamber can detect the presence of smoke at very low concentrations. The embedded and PC software complementing the LaserSCANNER provides a wide range of user-defined parameters and reporting capabilities. The detector easily interfaces with fire warning and fire suppression release systems and can be easily integrated into a building management system.

|

| VESDA LaserSCANNER |

Features

- Wide sensitivity range 0.005% obs/m to 20.0% obs/m (0.0015% obs/ft. to 6.24% obs/ft.)

- Each detector can cover an area of up to 2,000 m2 (20,000 sq. ft.)

- Four programmable alarm thresholds (Alert, Action, Fire 1 and Fire 2)

- AutoLearn feature

- Four pipe inlets

- Individual pipe flow monitoring

- Scans individual sectors once the smoke has been detected

- Replaceable air filter cartridge

- Option for inverted mounting

- Recessed mounting option

- Modular to meet site-specific requirements

- Modular Display Module and LCD Programmer

- Programmable relays (option for 7 or 12 relays available)

- High-efficiency aspirator

- Programmable General Purpose Input (GPI) to invoke operational modes

- PC programming and monitoring

- Multilingual displays

- Event Log for up to 18,000 events

These VESDA ® system features make it a versatile smoke detection product:

The VESDA ® LaserIndustrial (VLI)

The VESDA ® VLI is an industry-first early warning aspirating smoke detection system, designed to protect the business-critical industrial applications including mining, manufacturing, power generation facilities, waste treatment plants and more up to 2,000 m2 (21,520 sq. ft.).

Long life, intelligent, fail-safe technology

The VLI detector combines a fail-safe Intelligent Filter with an advanced clean-air barrier and Clean Air Zero for optics protection allowing the use of absolute detection and a long detection chamber life all enclosed in a robust IP66-rated enclosure without the need for re-calibration.

The Intelligent Filter:

Effectively reduces the level of pollution in the air sample before it enters the detection chamber, which dramatically extends the operational life of the detector in harsh and polluted environments.

It is fully monitored, therefore providing consistent sensitivity over the entire operational life of the detector.

|

| VESDA LaserINDUSTRIAL |

Installation, Commissioning and Operation

The VLI detector features a robust IP54-rated enclosure that provides protection against dust ingress and water splash. In the majority of applications, this eliminates the need to use expensive external IP enclosures, thus simplifying and reducing the cost of installation.

The VESDA ® VLI detector is equipped with a powerful aspirator that provides a total pipe length of 360m (1200 ft). It is fully supported by the ASPIRE2, VSC and VSM4 software applications which facilitate ease of pipe network design, system commissioning and maintenance together with compatibility with existing VESDA ® installations.

The AutoLearn commissioning assistant reduces setup time and ensures optimum alarm and low thresholds in a range of environments.

The VESDA®VLI detector features a standardized industry BACnet over Ethernet communication protocol for remote monitoring and programming and connection to building management systems (BMS) and automation devices.

The VESDA ® VLI detector is inherently less prone to nuisance alarms due to the intelligent filter, lint trap, sub-sampling probe and secondary filter. Coupled with its modular design.

The VESDA ® LaserCOMPACT-EX

The VESDA ®VLC-EX detector has been specifically designed to provide all the benefits of aspirating smoke detection, including very early warning, for the protection of hazardous applications with Zone 2 classification. It offers the same wide sensitivity range as the VESDA VLP and VESDA VLS — 0.005 to 20% obs/m (0.0016 - 6.25% obs/ft). The VESDA VLC-EX supports three configurable alarm levels (Alert, Pre-Alarm and Fire) and comes in two versions. One version interfaces via relays only (RO) and the other across either relays or VESDAnet (VN). The VLC-EX incorporates the well-proven VESDA VLP detection technology into an IP54 rated stainless steel enclosure.

The VESDA ® LaserCOMPACT-EX

The VESDA ®VLC-EX detector has been specifically designed to provide all the benefits of aspirating smoke detection, including very early warning, for the protection of hazardous applications with Zone 2 classification. It offers the same wide sensitivity range as the VESDA VLP and VESDA VLS — 0.005 to 20% obs/m (0.0016 - 6.25% obs/ft). The VESDA VLC-EX supports three configurable alarm levels (Alert, Pre-Alarm and Fire) and comes in two versions. One version interfaces via relays only (RO) and the other across either relays or VESDAnet (VN). The VLC-EX incorporates the well-proven VESDA VLP detection technology into an IP54 rated stainless steel enclosure.

Remote Displays and Programmer

The VESDA display module monitors and reports the

status of a detector, providing a visual representation of smoke levels along

with all alarm and fault conditions. The menu-driven VESDA Programmer allows

the user to conveniently configure, commission and maintain the VESDA system,

as well as a program each individual

detector.

VESDAnetTM

|

| VESDA HLI |

VESDAnet is a comprehensive, fault-tolerant, “closed,”

two-wire communications loop

that links VESDA detectors, displays,

programmers and remote relay modules on a daisy-chained loop. VESDAnet enables

a number of units to be programmed together from one or more locations and

automatically detects communication failures. It also easily interfaces with

systems external to the network,

such as intelligent fire alarm panels and

building management systems.

|

| VESDAnet |

VESDA Pipe

A key element in the performance of a VESDA ASD system is the sampling pipe network that actively transports air from the

protected area to the detector. VESDA offers an extensive range of pipes and

fittings to suit all application needs, ensuring a quality system is installed

every time. Some pipes and fittings are not available in

certain countries. To simplify the application of air sampling detection the VESDA is supplied with pre-engineered pipe network designs. Designers can simply apply these proven designs to typical installations and have confidence that they will work.

The VESDA ® Pipe Network being such an integral part of any VESDA ® Air Sampling System, maintaining its integrity and reliability is critical in ensuring a consistently accurate level of detection performance.

Reliable Air Flow Monitoring using Ultrasonic Sensing

With the VESDA ® Pipe Network being such an integral part of any VESDA ® Air Sampling System, maintaining its integrity and reliability is critical in ensuring a consistently accurate level of detection performance. The VESDA ® LaserFOCUS utilizes Ultrasonic Flow Sensing principles to assist in the measurement & monitoring of airflow. The VESDA ® LaserFOCUS detector immediately identifies and communicates any variances in the airflow rate.

|

| VESDA Fitting |

The VESDA ® Pipe Network being such an integral part of any VESDA ® Air Sampling System, maintaining its integrity and reliability is critical in ensuring a consistently accurate level of detection performance.

|

| VESDA Pipes |

With the VESDA ® Pipe Network being such an integral part of any VESDA ® Air Sampling System, maintaining its integrity and reliability is critical in ensuring a consistently accurate level of detection performance. The VESDA ® LaserFOCUS utilizes Ultrasonic Flow Sensing principles to assist in the measurement & monitoring of airflow. The VESDA ® LaserFOCUS detector immediately identifies and communicates any variances in the airflow rate.

In this application, the ultrasonic .ow sensing technology was adapted to monitor air rather than liquids. Two transducers (Blue) are used to continually send signals to each other. One signal travels with the flow (Violet), the other against (Yellow). The time difference between the two signals is used to calculate the rate of airflow within the pipe.

Xtralis VSM4TM

The VSM software package allows the user to monitor, configure and control a VESDA the system from a central location via a VESDAnet communication loop or directly to VESDA detectors. Real-time and historical events for a single detector or multiple networks of detectors can be collected over a local- or wide-area network. The data then can be processed and presented in either report or graphical format — even graphically on site floor plans.

Xtralis VSCTM

Xtralis VSM4TM

The VSM software package allows the user to monitor, configure and control a VESDA the system from a central location via a VESDAnet communication loop or directly to VESDA detectors. Real-time and historical events for a single detector or multiple networks of detectors can be collected over a local- or wide-area network. The data then can be processed and presented in either report or graphical format — even graphically on site floor plans.

|

| Xtralis VSM4 |

The

VSC software package can be used to configure, commission and maintain VESDA

detectors. The software provides high-level programming flexibility through its

on-line and off-line configuration capabilities. Rapid diagnostic abilities,

concurrent configuration views, compare/merge functionality, and simultaneous smoke-trend graphing of

multiple detectors are other standard features designed to simplify operation

and installation setup.

|

| VSC Configuration |

VESDA ASPIRETM

VESDA

ASPIRE is the latest version of VESDA sampling pipe network design and modeling

software. It aids in the design and evaluation process for basic to very

complex pipe-network layouts. Key features, such as design wizards, 3-D

isometric views, an automated design verification process, and a new

AutoBalance capability, ensure that a tailored pipe layout is easily achieved.

The Installation Data Pack (IDP) generates a series of reports with parameters,

required materials and expected system performance so installation and

commissioning engineers receive this information clearly.

|

| VESDA Aspire |

Analysis and Diagnostics with the Instant Fault Finder

To ensure ongoing system integrity, immediate assessment of the detector's condition is critical. By opening the service access door, the operator can activate the Instant Fault Finder feature - a smart diagnostic feature that converts the smoke dial into a fault indicator. It provides instant and meaningful information on the detector's status without the need for additional programming and evaluation tools. Now the service and maintenance staff can be better informed before arriving onsite, reducing the time on site, and saving on maintenance costs.

Supporting Efficient System Setup - AutoLearn

Simplifying the setup, installation and commissioning of high sensitivity air sampling technology was one of the key drivers behind the design of the VESDA®. VESDA®s AutoLearn feature supports this process by assessing environmental conditions, automatically setting an acceptable smoke alarm and flow fault thresholds.

GAURAV SARASWAT :-ENERGYINFO

- Get link

- X

- Other Apps

Labels:

LaserCOMPACT

LaserFOCUS

LaserINDUSTRIAL

LaserPLUS

LaserSCANNER

VESDA

VESDA ASPIRE Software

Xtralis VSC Software

Xtralis VSM4 Software

Location:

Ramnagar, Uttarakhand 244715, India

- Get link

- X

- Other Apps

Comments